This week is all about windows! The skilled guys from Rogers Building Corporation have been carefully reconstructing and reinforcing the walls around the windows and the windows themselves. Using craftsmanship, time and patience, they have nearly completed the upper west window that was almost falling out of the structure when they started. Utilizing unique and period accurate details like the bird’s-mouth catch and corbeled arches, the restoration is really something to see!

Reinforcing the walls around the windows on the first floor.

The upper west window, finally secure. The walls and windows have both been reinforced. The vertical piece of wood in the middle has twine wrapped around it, connected to both sides of the window arch. By winding it, the tension increases, essentially pulling the sides of the arch together, creating more support.

Reproduction and salvage glass panes looking out over the roof of the poultry shed and the carriage house.

A close up of the wall around the arched upper west window.

The traditional bird’s-mouth catch holding the window open to let in a breeze.

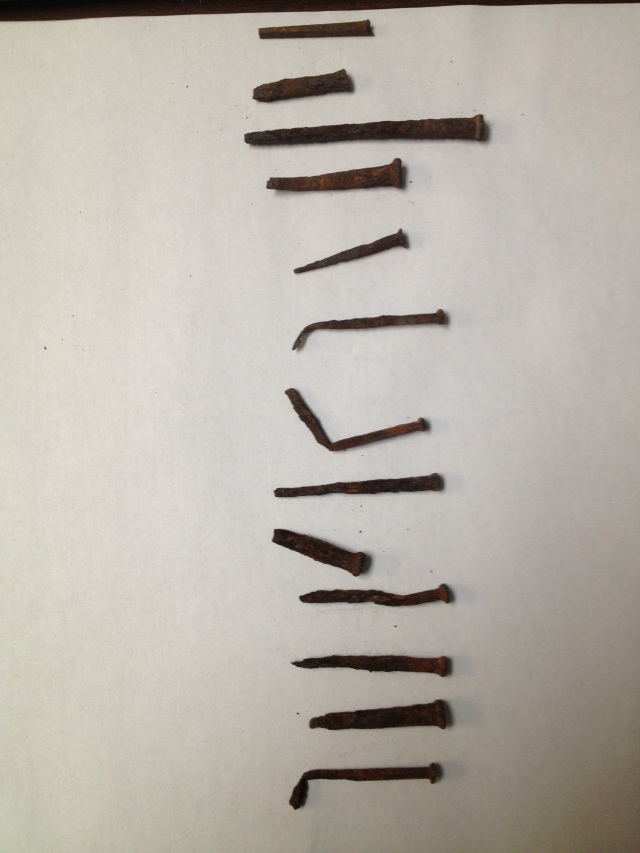

Detail of the bird’s-mouth catch. This type of catch would have been typical of this kind of structure and RBC has used period accurate screws, paying close attention to the details of restoration.

Detail of the type of reinforcement done to the windows. This corbeled arch provides support where the original wood had decayed over time.

The upstairs work bench with a section of corbeled wood. It takes time, patience and skill to make the wood bend, fit and support.